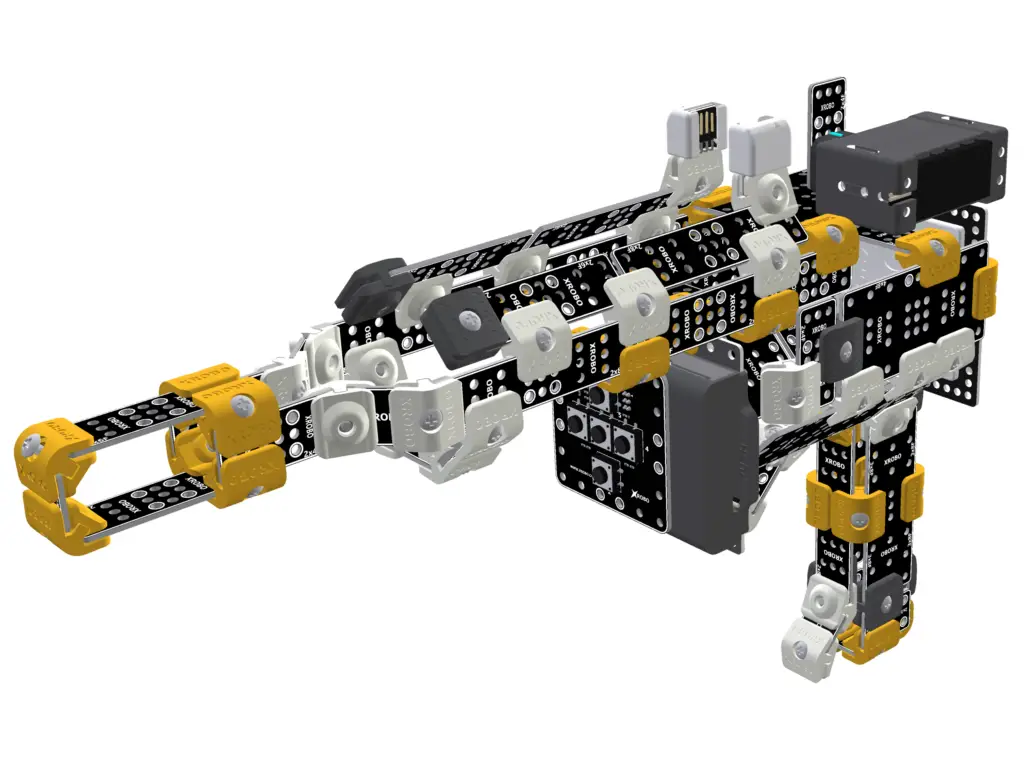

1. Robot Assembly

1) Assembling the Robot

- Please refer to the manual for assembling the robot.

- Ensure all components are properly connected.

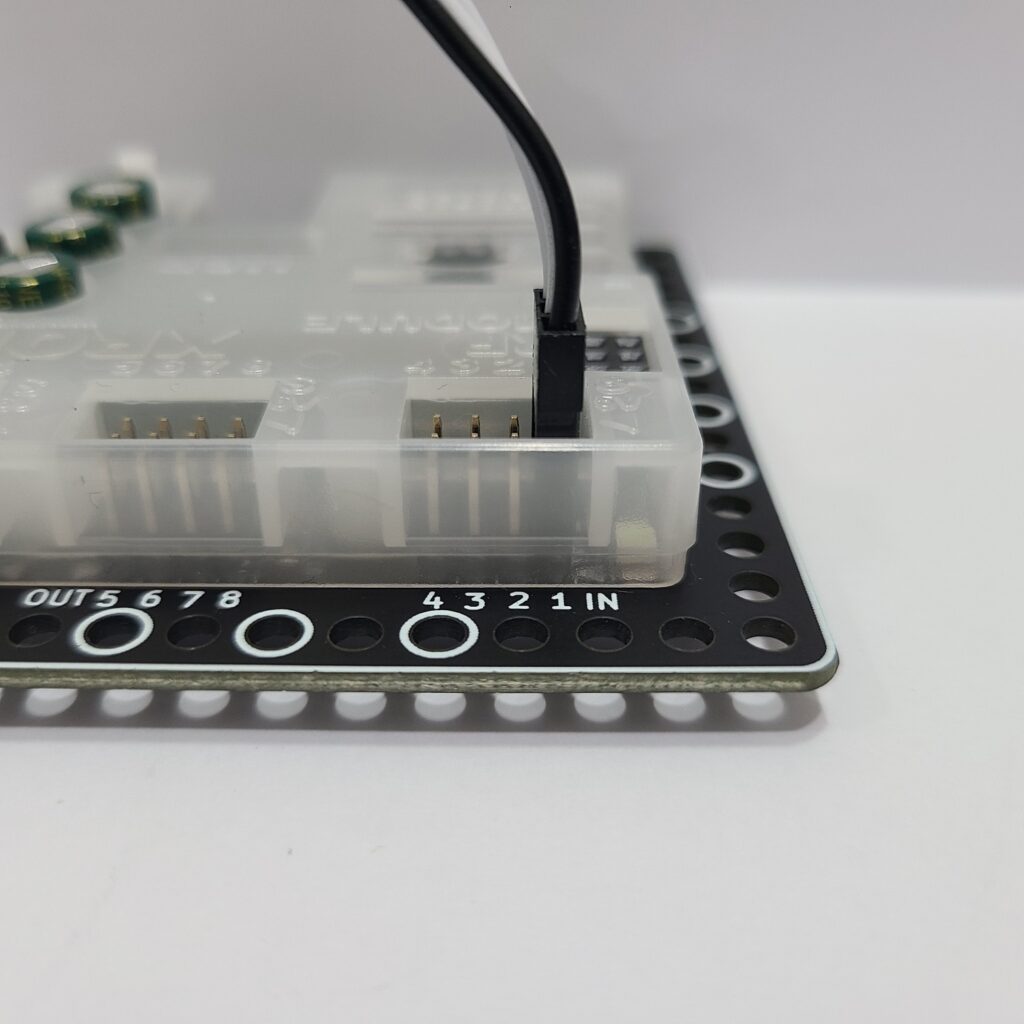

2) Verifying Cable Connections

- X-Keypad controlling the rifle → IN1 port

- Servo motor moving the rubber band hanger → OUT1 port

- LED 1 on the left → OUT2 port

- LED 2 on the right → OUT3 port

2. Code Upload & Robot Operation

Without Direct Coding, when using the Complete Robot Operation Program provided by XROBO

When Directly Coding individual robot operation programs

1) When using the Complete Robot Operation Program

- If the X3 Operation Program is already uploaded, to the robot, please proceed directly to Operate Robot.

① Preparing for Upload

- Ensure mBlock is installed on your computer. If not, please install mBlock.

- To operate the robot, you will need a download board and a download cable. If you do not have these components, please purchase them.

② Download and Load the Operation Program

- Please refer to the Using the Operation Program page to download the X3 Operation Program and load it into mBlock.

③ Uploading the Code

- Upload the code to the robot by following the instructions on the upload method page or video (starting at 34 seconds).

④ Operating the Robot

- ① Turn on the power to the CPU board.

- ② Press and hold the START button for more than 2 seconds. Release it when you hear the "Do Re Mi Fa Sol La Ti Do" melody.

- ③ Press the START button 1 times to select the "Do" tone.

- ④ Turn on the power to the remote control and have fun controlling the robot.

2) If You Are Coding the Program Yourself

① Preparing for Upload

- Ensure mBlock is installed on your computer. If not, please install mBlock.

- To operate the robot, you will need a download board and a download cable. If you do not have these components, please purchase them.

② Coding the Program

- Launch mBlock and freely code your program by referring to the coding examples or the manual.

③ Uploading the Code

- Upload the code to the robot by following the instructions on the upload method page or video (starting at 34 seconds).

④ Operating the Robot

- ① Turn on the power to the CPU board.

- ② Briefly press the START button on the CPU board and then release it.

- ③ Turn on the power to the remote control and have fun controlling the robot.

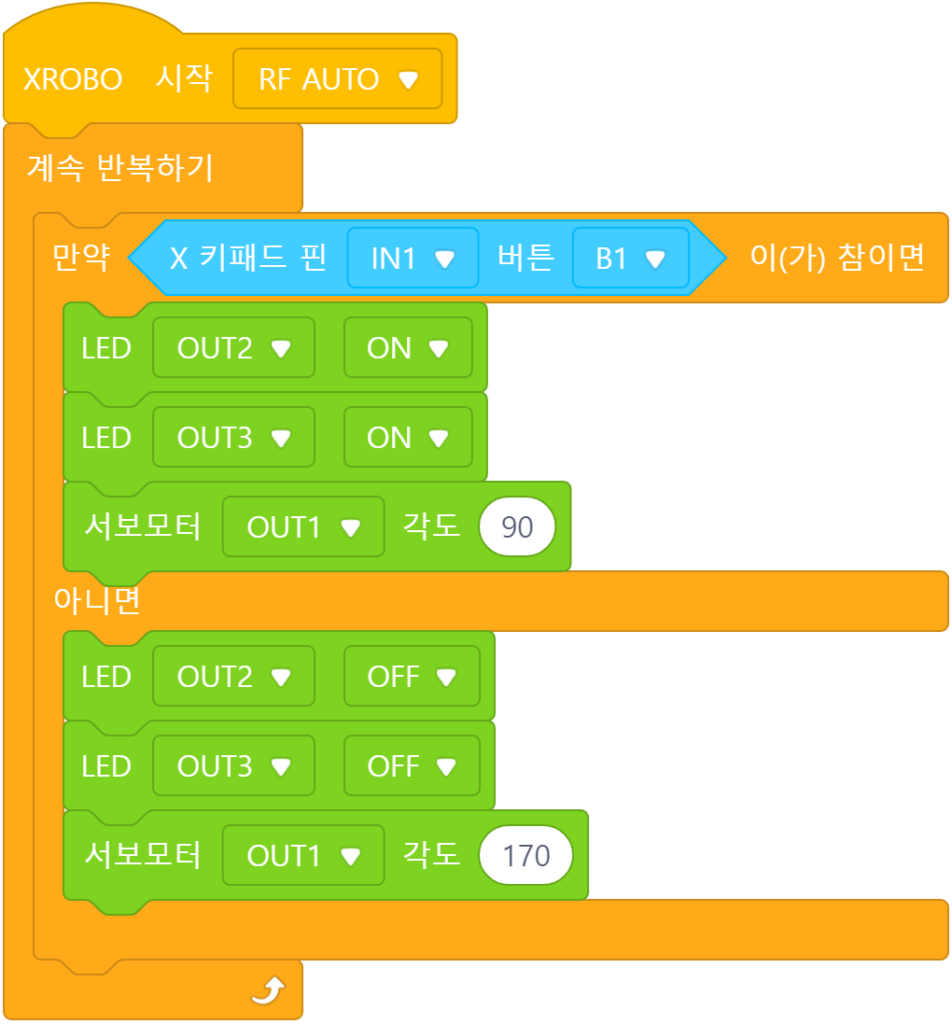

3. Coding Examples

- To check the answer, swipe the image to the side.

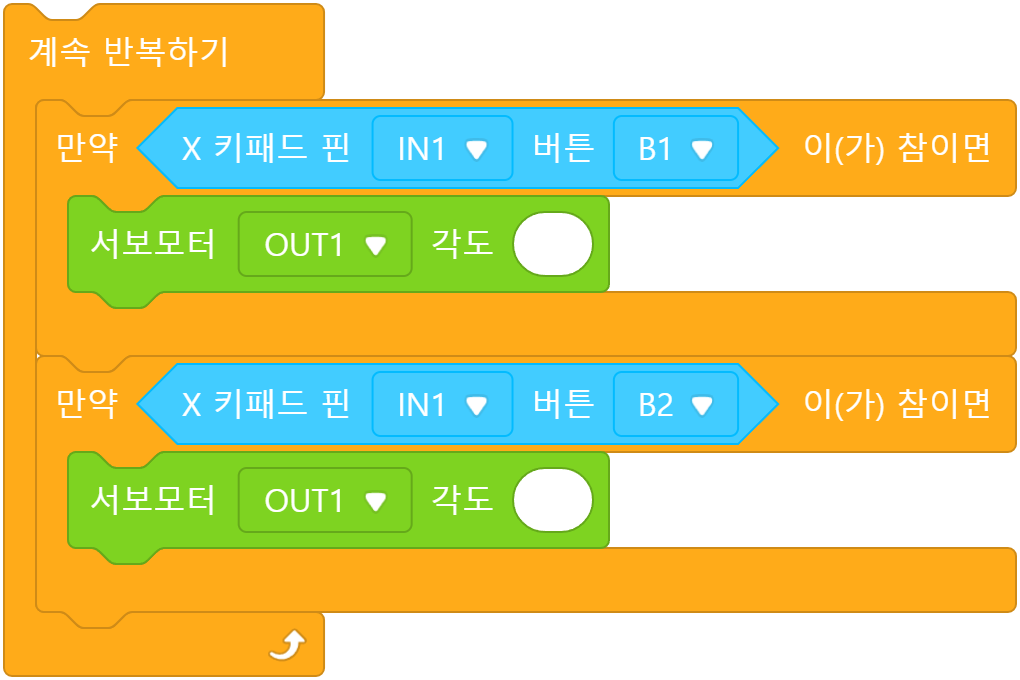

1) Adjusting the Rubber Band Hanger

Lowering the Rubber Band Hange

Set the servo motor angle to 90.

Since the servo motor is connected to the OUT1 port, select ‘OUT1’ when choosing the port.

Raising the Rubber Band Hange

Set the servo motor angle to 170.

2) Firing the Rubber Band with the X-Keypad

When the X-Keypad button is pressed:

- Button 1: Lower the rubber band hanger

- Button 2: Raise the rubber band hanger

Since the X-keypad is connected to the IN1 port, select ‘IN1’.

Only when X-Keypad button 1 is

- Pressed: Lower the rubber band hanger

- Released: Raise the rubber band hanger

If you want the robot to operate only while the button is pressed, use the ‘if-else’ block.

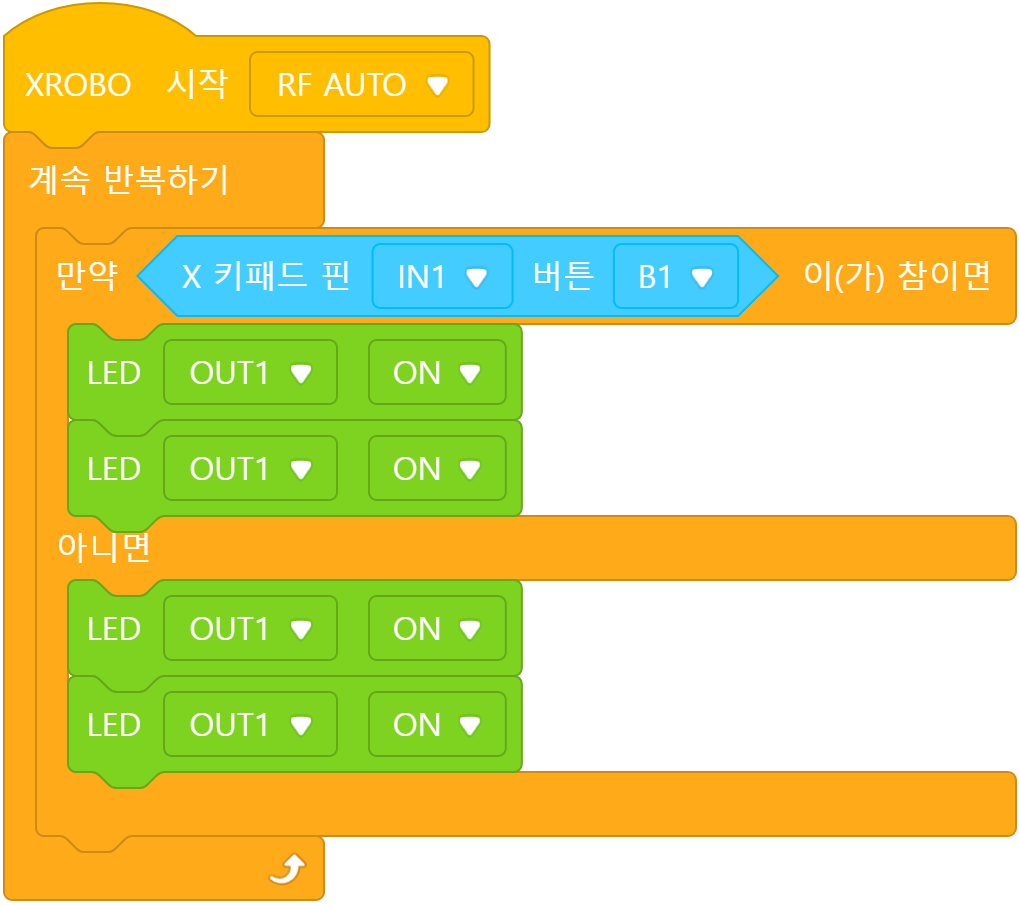

3) Turning on the LED when Firing the Rubber Band

When the X-Keypad button is pressed:

- Button 1: Turn on the LED and lower the rubber band hanger

- Button 2: Turn off the LED and raise the rubber band hanger

Since LED 1 and LED 2 are connected to OUT2 and OUT3 ports, respectively, select the ‘OUT2’ and ‘OUT3’ ports.

Only when X-Keypad button 1 is

- Pressed: Turn on the LED and lower the rubber band hanger

- Released: Turn off the LED and raise the rubber band hanger

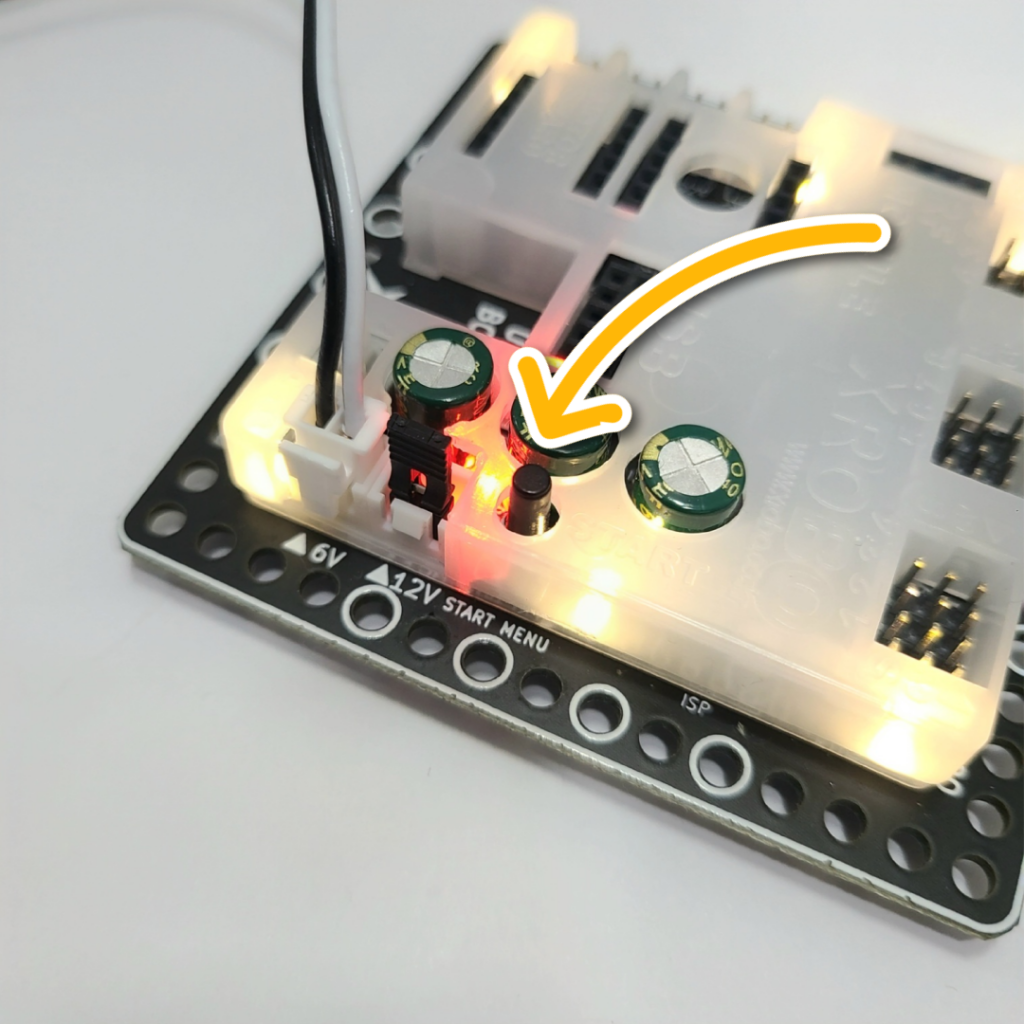

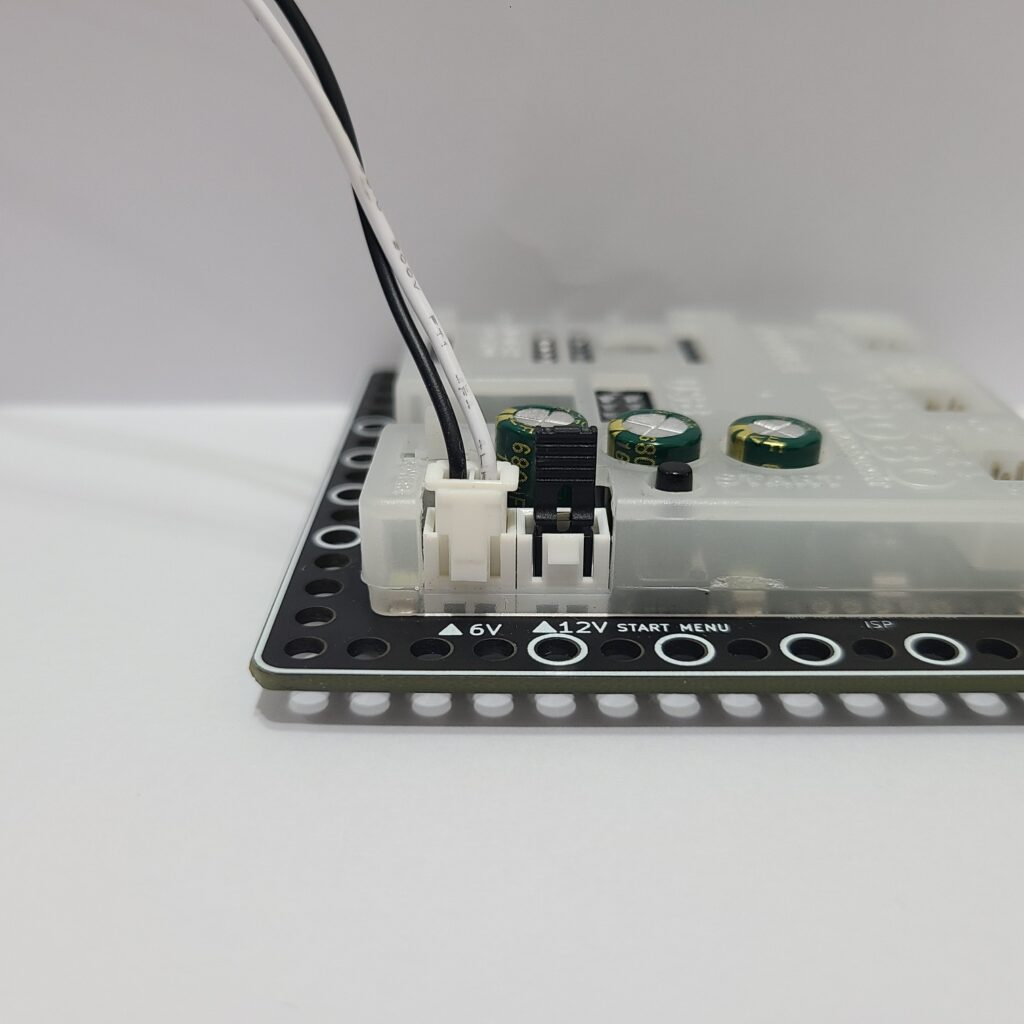

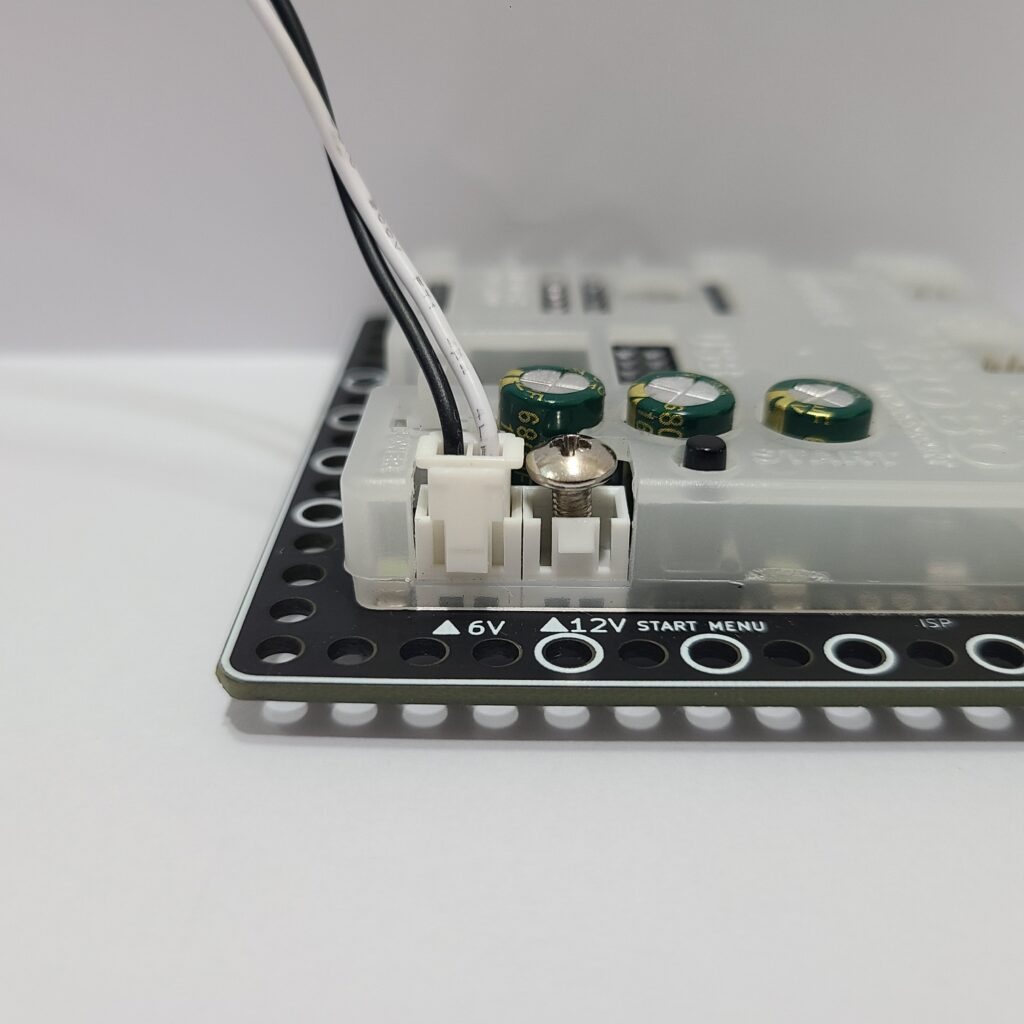

4. Troubleshooting Robot Issues

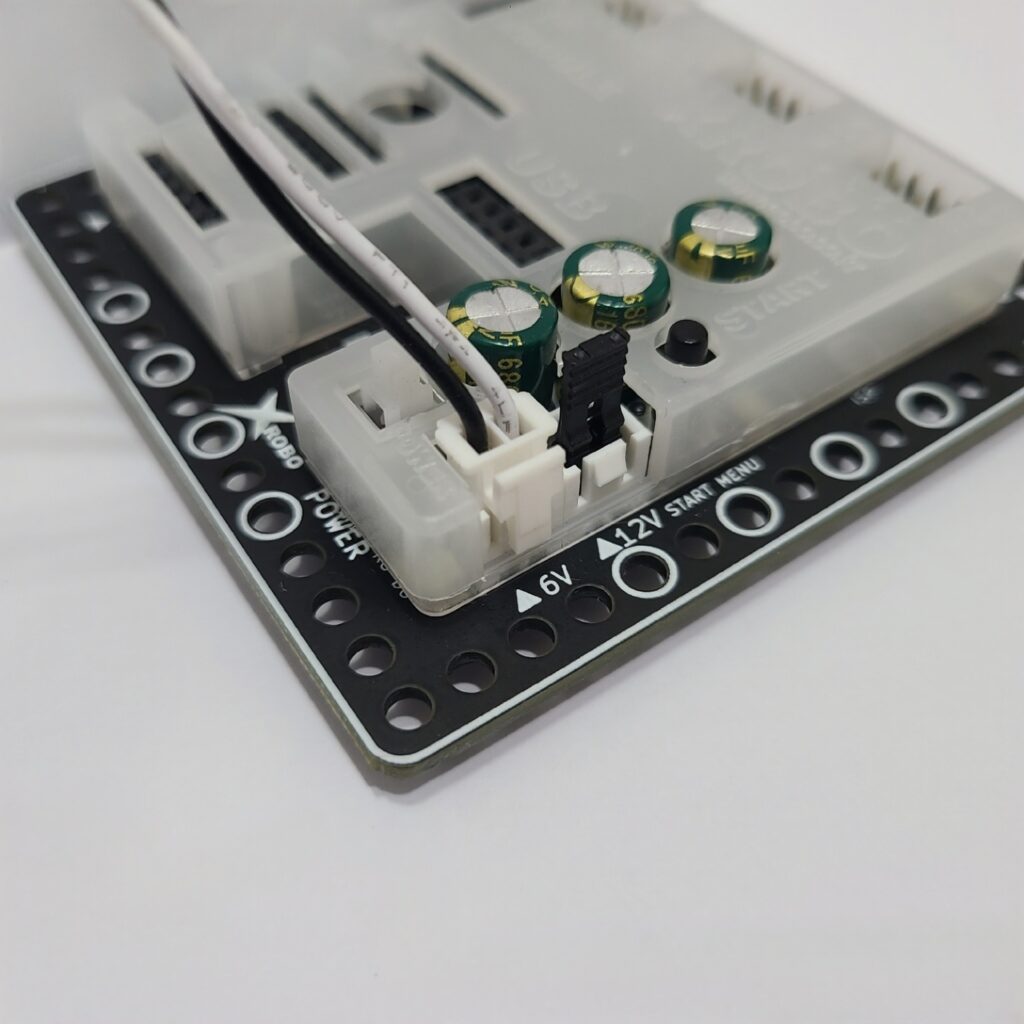

1) When the Power Does Not Turn On

- Ensure the batteries are inserted with the correct polarity, matching the ‘+’ and ‘-‘ signs.

- Verify that the jumper cap is properly inserted into the 12V power connector on the CPU board.

- If there is no jumper cap available, use a 3×8 bolt to connect to the 12V power connector as an alternative.

- Inspect the battery pack cable for any breaks or disconnections.

- Ensure that the battery pack cable is securely connected to the 6V power connector on the CPU board.

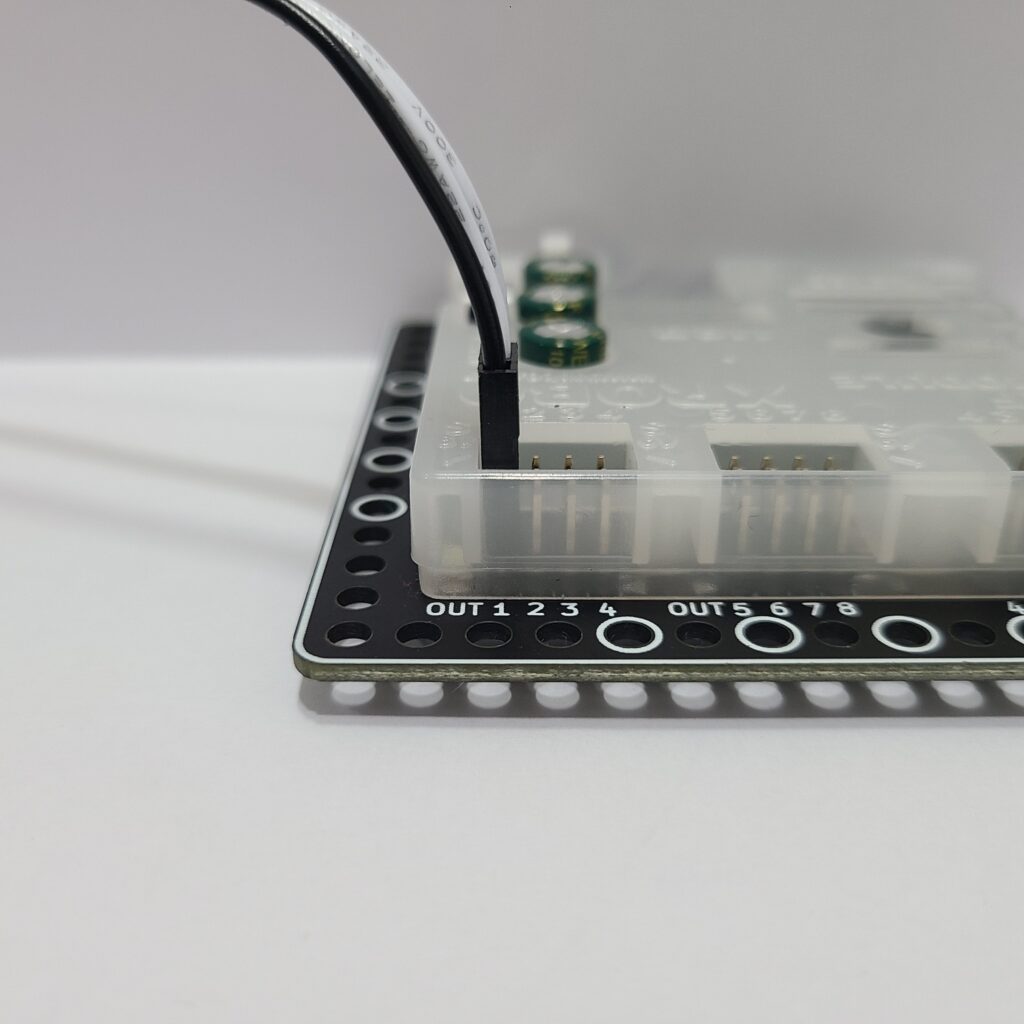

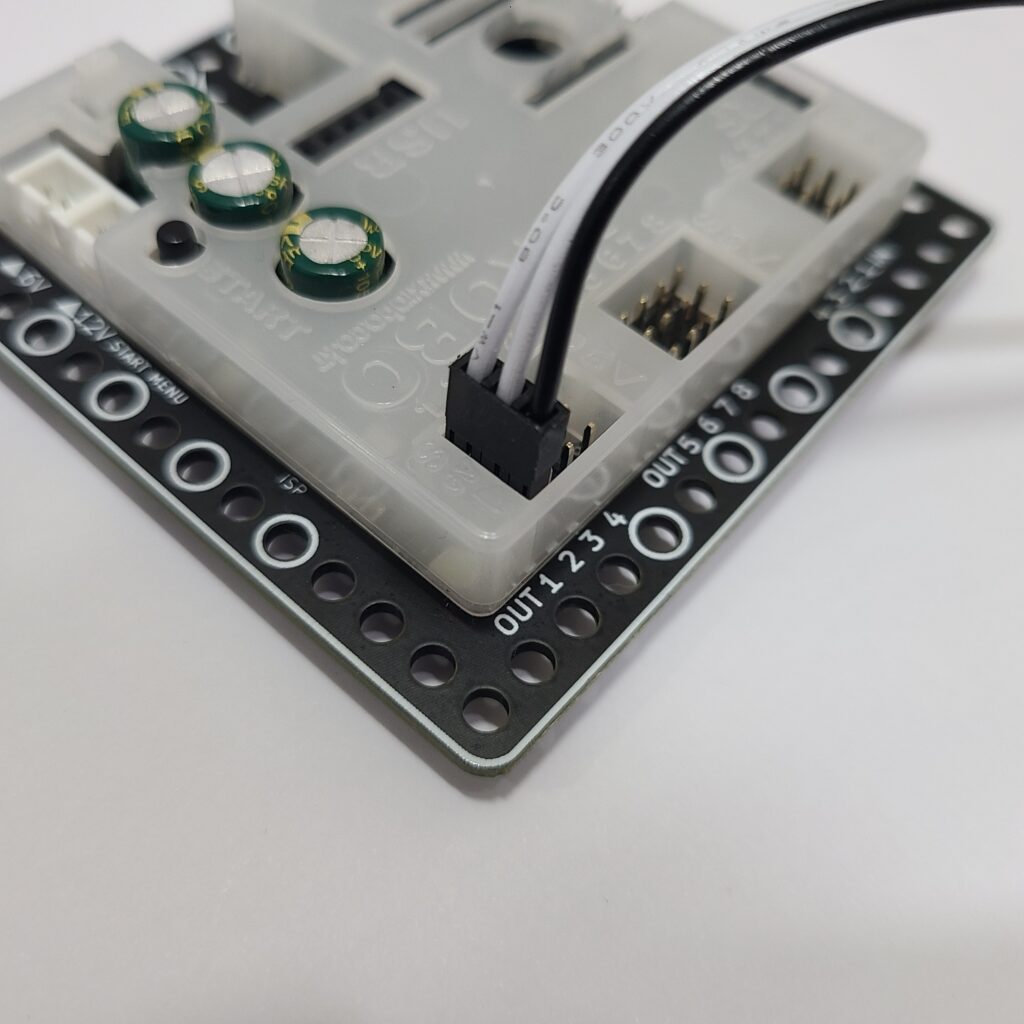

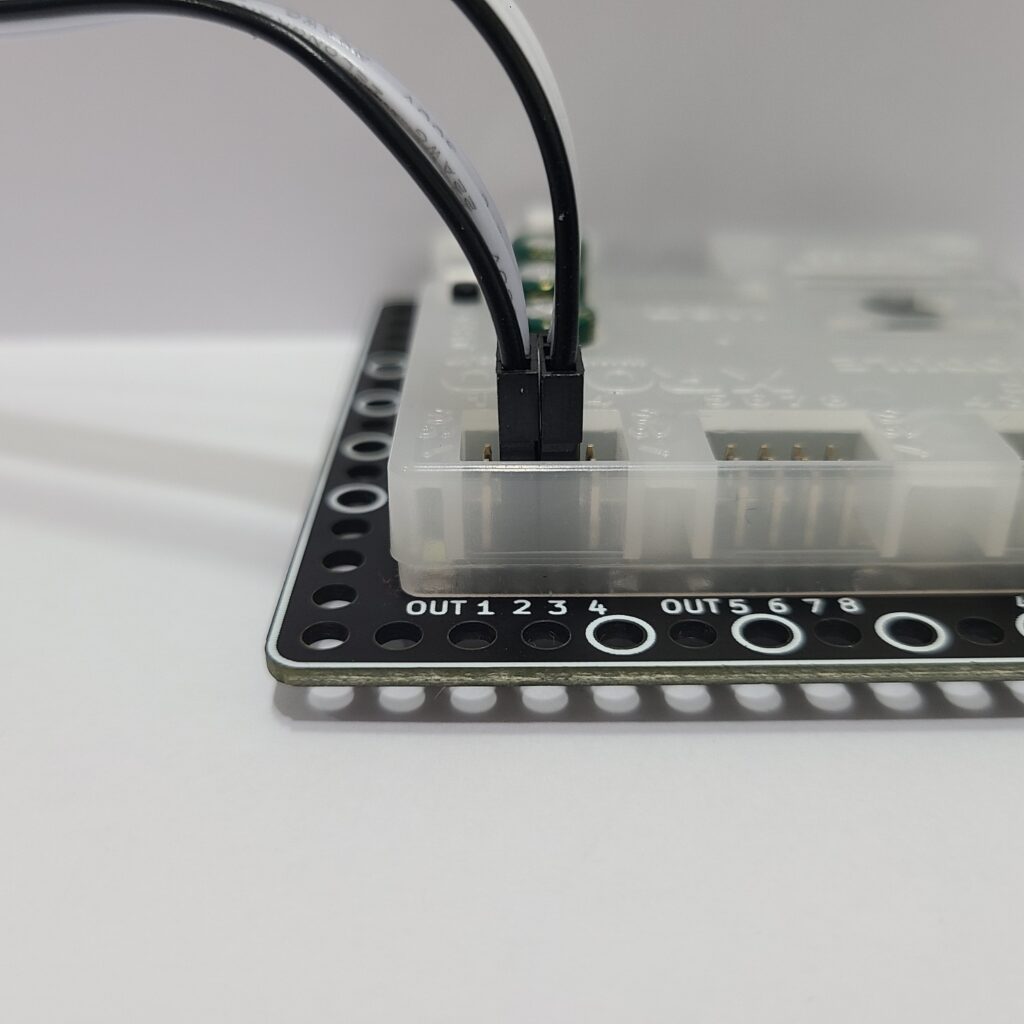

2) When the Servo Motor is Not Functioning Properly

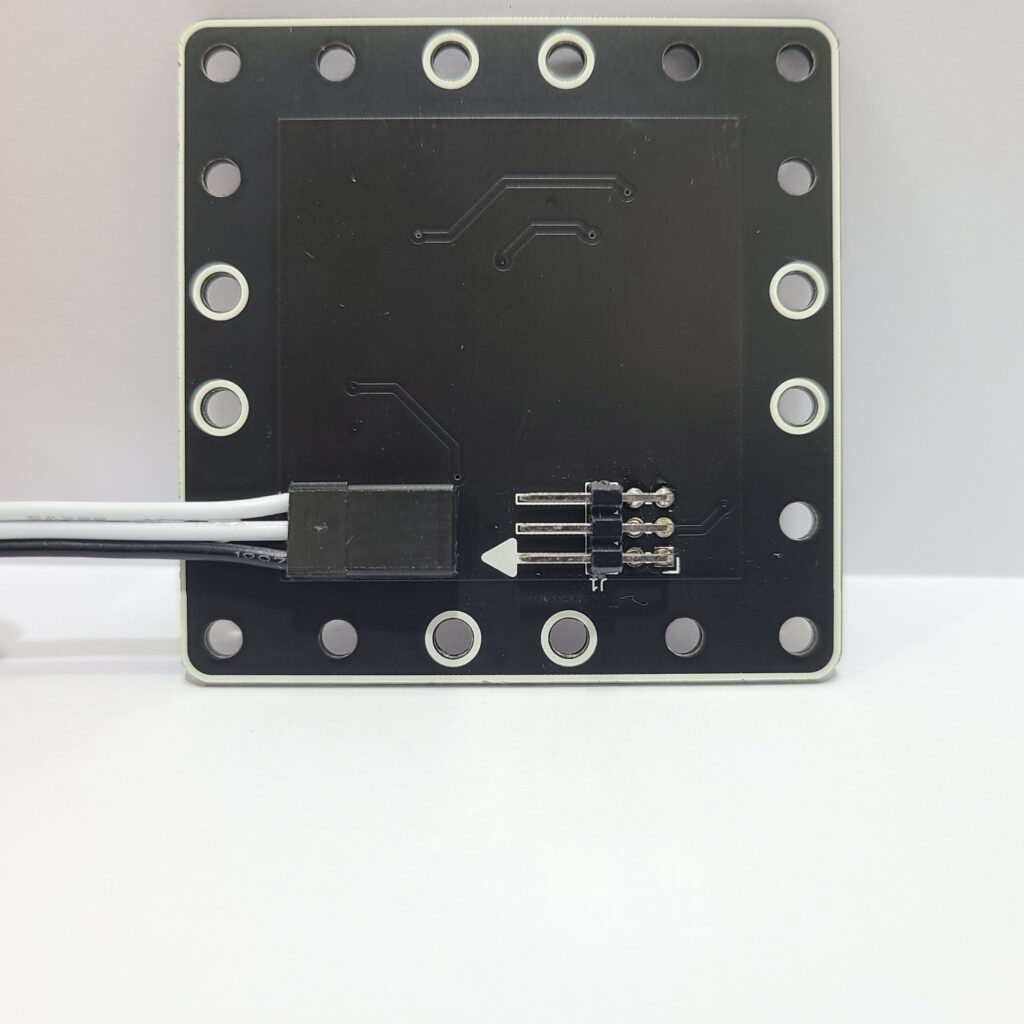

- Ensure that the 3-PIN cable is connected to the correct OUT port.

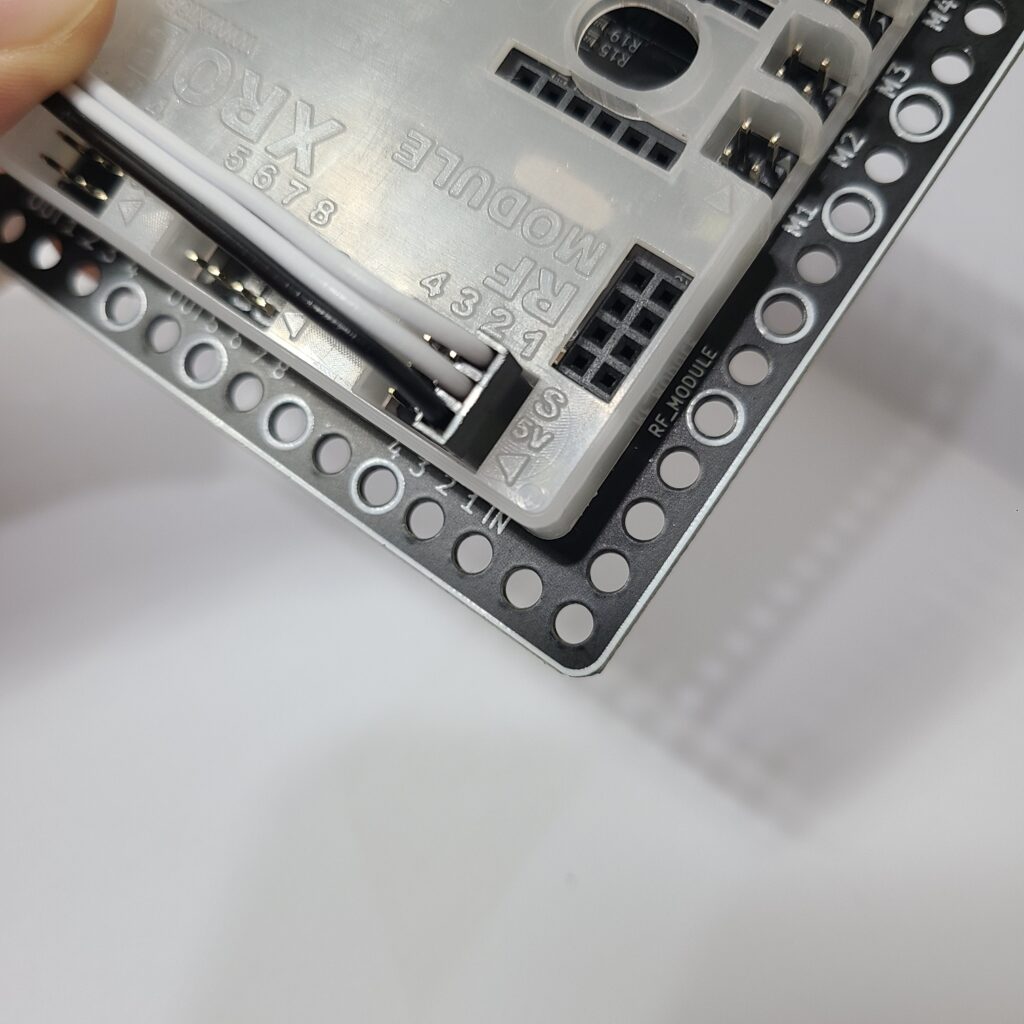

- Verify that the black wire of the servo motor cable is plugged in the direction of the arrow on the CPU board case.

- Connect the cable so that the black wire aligns with the arrow on the CPU board.

- Ensure that the direction of the servo motor label in the assembled robot matches the assembly diagram. If the label is oriented incorrectly, the servo motor may operate in reverse, or the angle may be incorrect, posing a risk of gear damage.

3) When the LED is Not Functioning Properly

- Ensure that the 3-PIN cable is connected to the correct OUT port.

- Verify that the black wire of the 3-PIN cable is plugged into the side of the LED pin with the white line.

- Confirm that the black wire of the 3-PIN cable is connected in the direction of the arrow on the CPU board case.

4) When the Robot Operates Abnormally

- Check that the cables are not caught in the drivetrain. If the cables are entangled with the drivetrain, the robot may not function properly.

- Verify that the black wire of the 3-PIN cable is connected to the side with the white line on the X-keypad pin. (Inserting the 3-PIN cable in reverse can cause a short circuit, resetting the CPU board.)

- Ensure that the black wire of the 3-PIN cable is aligned with the arrow on the CPU board case. (Reversing the 3-PIN cable can cause a short circuit, resetting the CPU board.)